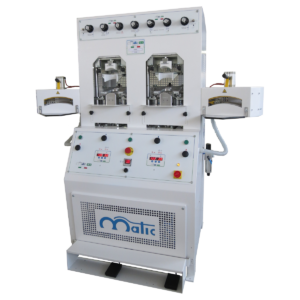

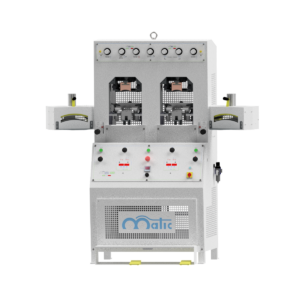

M51S

Toe Forming Machine

- One COLD station for STROBEL, NORM or STITCH-DOWN preparation

- One HOT stations for toe puff reactivation

- Pneumatic Balancing Kit, Double stroke, special Teflon

- Teflon end stroke quick adjustments

- Hydraulic control of second descent