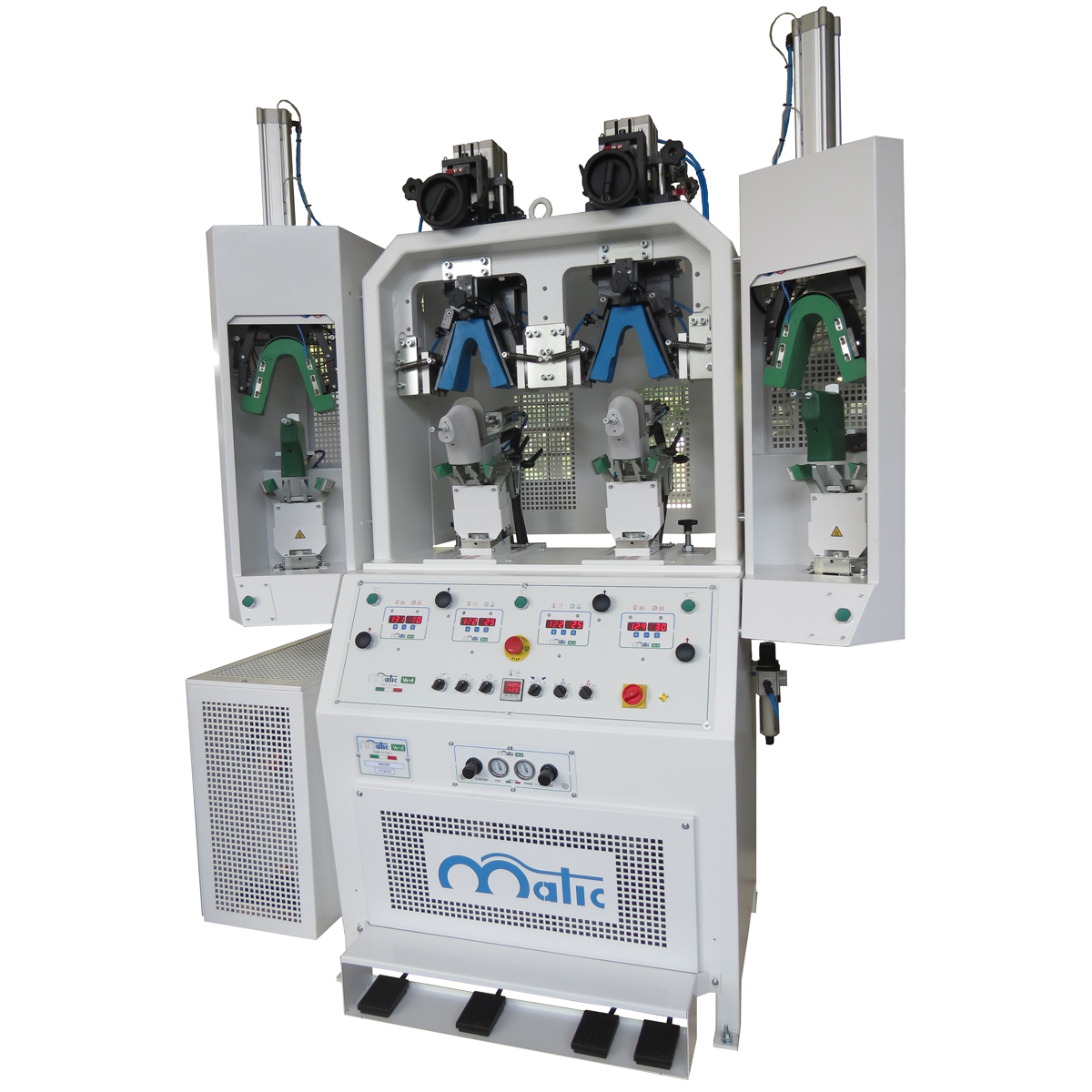

Dimensions: cm 160 x 87 x 210 (height)

Dimensions with packing: cm 175 x 110 x 225 (height)

Weight: net (machine) kg 640 – gross (with packing) kg 830

Electrical consumption: kw 2.4

Note: technical data could be changed without notice.

S: pincers variable direction for 1 station

PZR: pincers widht quick adjustable for 1 station

BSP: pneumatic back stop plate for 1 station

4RP: two additional reactivating stations complete of alu and rubber moulds and pincers

GY: goodyear flanging kit: special wiper holders, wipers, back alu-blocks and BSP pneumatic back stop plates